Introduction

Coatings play an indispensable role in the protection and enhancement of flat roofs in commercial and residential settings. Serving as the first line of defense against environmental forces, these coatings are tailored to offer resistance against leaks, ultraviolet rays, and more.

Key Takeaways

- Flat roof coatings offer leak prevention, UV resistance, enhanced durability, energy efficiency, and reduced maintenance needs.

- These coatings extend roof life and improve performance against environmental factors.

- Selection factors include substrate type, local weather, durability, water resistance, and cost-quality balance.

- Application involves thorough surface preparation, priming, various application methods, and sufficient curing time and regular maintenance and repairs are crucial for maximizing roof and coating lifespan.

What Do They Do?

Flat roof coatings are protective layers applied to the surface of flat roofs to prevent leaks, resist water, reflect sunlight, and provide durability.

They are particularly essential for extending the life of flat roofs and enhancing their performance by protecting them from the elements and environmental factors.

Benefits of Using Coatings

Flat roof coatings offer multiple advantages, such as:

- Leak Prevention: They form a seamless, waterproof membrane that guards against leaks.

- UV Resistance: Coatings provide protection against harmful UV rays, preventing degradation and wear.

- Enhanced Durability: They protect the roof from environmental elements, extending its lifespan.

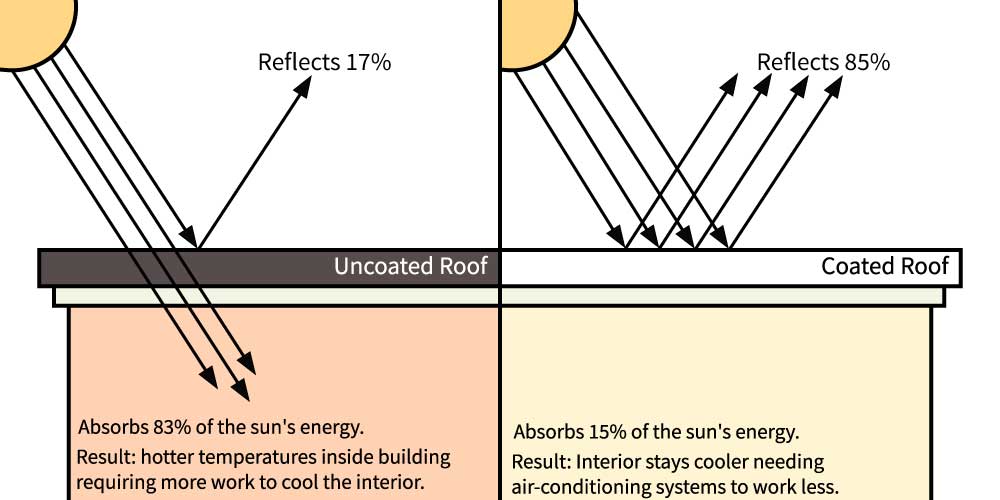

- Energy Efficiency: Reflective coatings can lower roof temperatures and reduce cooling costs.

- Reduced Maintenance: Quality coatings result in lesser maintenance requirements and repair needs.

Factors to Consider When Choosing a Flat Roof Coating

- Kind Of Substrate: The type of underlying roof material affects the choice of coating.

- Environmental Factors: Local weather conditions, like extremes of temperature and levels of precipitation, influence coating selection.

- Durability And Reflective Properties: Coatings with high durability and reflectiveness are preferable in harsh and sunny climates.

- Ponding Water: For roofs with water accumulation issues, water-resistant coatings are vital.

- Cost And Quality Of Materials: Balancing cost with quality ensures optimal protection without overspending.

Different Types of Flat Roof Coatings

Silicone Coatings

Excellent Weather Resistance: They are known for their ability to withstand harsh weather conditions, including ultraviolet (UV) light exposure, oxidation, and extreme weather variations.

Long-Lasting Physical Properties: Remain unreactive and maintain their physical properties for an extended period, making them suitable for areas with extreme weather fluctuations.

Energy-Efficient: They have high reflectivity, which helps in reducing energy costs by minimizing heat absorption. This can contribute to energy savings in various applications.

Attraction To Dirt And Dust: A drawback of silicone coatings is their tendency to attract dirt and dust, which can accumulate over time and reduce their reflectivity. Regular cleaning is necessary to maintain their performance.

Acrylic Coatings

Cost-Effective And Eco-Friendly: These coatings are water-based solutions and are known for their affordability and environmentally friendly characteristics.

Reflective Properties: They are primarily used for their ability to reflect a significant amount of UV rays, which helps reduce cooling costs in warmer climates. This adds another layer of roofing insulation and can lead to energy savings in cooling systems.

Easy Application: Are typically applied using common tools like rollers, brushes, or spray equipment, making the application process straightforward.

Susceptibility To Ponding Water: One limitation of acrylic coatings is their vulnerability to wear and tear when exposed to ponding water situations. Proper roof drainage systems are necessary to prevent damage and ensure optimal performance.

Performance In Prolonged Water Exposure: They may not perform optimally under extended exposure to water, emphasizing the importance of adequate drainage systems to maintain their effectiveness.

Elastomeric Roof Coatings

Elastomeric coatings are rubber-like protective membranes that can be applied to a range of roof substrates.

Flexibility And Durability: These coatings are known for their flexibility, durability, and ability to stretch and return to their original form. This makes them well-suited for regions with significant temperature fluctuations.

Waterproofing And Sealing: They provide effective waterproofing and can seal roof leaks, cracks, and imperfections, enhancing the integrity of the roof.

Energy Efficiency: They reflect sunlight and UV rays, reducing the heat load on the building. This contributes to energy efficiency and potential cost savings in cooling systems.

Thickness Matters: Monitoring the thickness of the application is crucial, as inadequate thickness can compromise the coating’s performance. Proper application is essential to ensure the coating’s effectiveness and is why you should have the work carried out by a reputable commercial roof contractor.

Polyurethane Coating

High Tensile Strength And Waterproofing: Polyurethane coatings are known for their remarkable tensile strength and ability to create seamless waterproof barriers.

Durability And Resistance: They form a durable and resistant layer that offers superior protection against foot traffic, mechanical damage, and harsh weather conditions.

Temperature Variation Suitability: Polyurethane coatings are well-suited for regions with significant temperature fluctuations and environments requiring exceptional puncture resistance.

Sensitivity To Moisture During Application: One potential drawback is their sensitivity to moisture during application, emphasizing the need for a dry substrate to ensure optimal adhesion.

Application Process for Flat Roof Coatings

Surface Preparation

Surface preparation is the bedrock of applying flat roof coatings, and its significance can’t be understated. Proper preparation ensures that the coating adheres effectively to the roof surface, providing a durable and long-lasting protective layer. The process involves cleaning the roof surface thoroughly to remove dirt, dust, grease, and any loose or damaged roofing material. The removal of contaminants is crucial as they can inhibit adhesion, compromising the coating’s efficacy and longevity. Any existing leaks or damages should be repaired, and protrusions like vents and pipes need to be sealed to create a uniform surface. Once cleaning and repairs are completed, the roof should be inspected to ensure that no imperfections remain that could affect the coating application.

Priming

Priming is the next critical step in the application process and is indispensable when the roof surface materials have adhesion issues. A primer serves as an intermediary layer between the roof surface and the coating, promoting better adhesion and enhancing the coating’s protective properties. It is especially necessary for surfaces that are rusty or have residues that are difficult to remove completely. Additionally, priming helps in sealing the pores of the roofing substrate, providing a smoother surface for the coating application, and it can enhance the performance of the coating, ensuring it lasts longer and resists environmental degradation effectively.

Application Methods

Once the surface is prepared and primed, the coating can be applied using various techniques and equipment, depending on the type of coating and the manufacturer’s recommendations. Common application methods include using rollers, brushes, or spray equipment. Rollers and brushes are typically used for smaller areas or where precision is required, such as around protrusions. On the other hand, spray equipment is suitable for covering large areas quickly and uniformly. Some coatings may require multiple layers, and it is crucial to ensure that each layer is applied evenly and allowed to dry before applying the next to avoid imperfections and ensure uniform thickness across the roof surface.

Curing Time

After the application, the coating needs sufficient time to cure. Curing time can vary depending on the type of coating, environmental conditions like temperature and humidity, and the thickness of the application. Generally, it can range from a few hours to several days. The curing process allows the coating to harden and adhere properly to the roof surface, providing a resilient and durable protective layer. Factors such as high humidity levels and low temperatures can prolong curing time, so it is important to consider the weather conditions during application. A fully cured coating maximizes the roof’s protection against UV rays, water infiltration, and other environmental factors.

Maintenance and Repairs

Regular maintenance involves inspecting the roof for damages, cleaning the surface to remove accumulated debris, and reapplying the coating as needed. Repairs should be carried out promptly if any damages or wear are detected, ensuring the coating remains effective in protecting the roof and maintaining its integrity. Maintenance and repairs are essential to maximizing the life and efficiency of both the roof and the coating.

Conclusion

Flat roof coatings are quintessential for maintaining the integrity and extending the lifespan of flat roofs, making them an integral component in roof management. These coatings not only offer a protective shield against environmental factors but also enhance the energy efficiency and durability of the roofs. The assortment of coatings available, such as silicone, acrylic, elastomeric, and polyurethane coatings, offer tailored solutions to meet varied needs and environmental conditions.

Frequently Asked Questions

What are the benefits of applying coatings to commercial flat roofs?

Coatings can extend the roof’s life, improve energy efficiency by reflecting sunlight, resist UV damage, and provide waterproofing. They are cost-effective compared to roof replacement.

How long do commercial roof coatings typically last?

The lifespan varies depending on the material and environmental conditions, but most high-quality roof coatings can last between 10 to 20 years with proper maintenance.

Can roof coatings be applied to any type of commercial flat roof?

Most coatings are versatile but check with the manufacturer. They’re suitable for various materials like metal, asphalt, or rubber, but some roofs may need repairs before coating.

Are there environmentally friendly options for commercial roof coatings?

Yes, there are eco-friendly options like acrylic and silicone coatings. They are low in volatile organic compounds (VOCs) and reflect sunlight, reducing the building’s cooling needs.

How does weather affect the application and performance of roof coatings?

Weather significantly affects both. Ideal conditions are dry and moderate temperatures. Extreme heat or cold can hinder proper curing, and moisture can compromise adhesion.